66-67 Dodge Charger Source Guide

Speedometer

CablePosted by Wes on 04/01/08NAPA #615-1605 Posted by Ron Bianchi on 12/5/07 Jim's Auto Parts catalog: a speedometer cable for 67 down, all A,B & E bodies is $19.00 Black casing( as original) and $24.00 gray casing. This price also includes the firewall grommet. Jim's Auto part number :TR-1463B black TR-1463G gray |

| Posted by Duane Pankhurst on 08/24/05

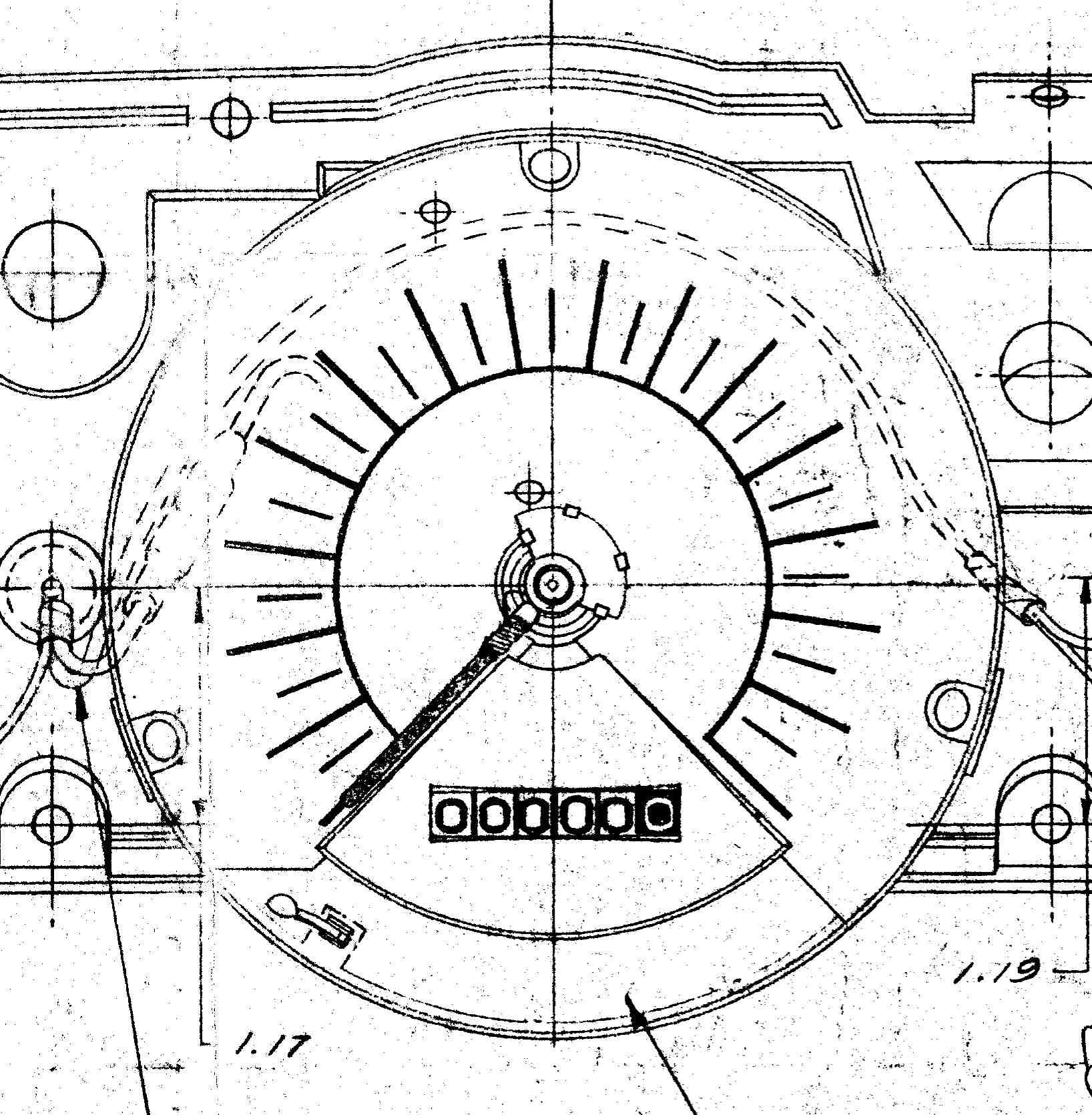

Scanned from Stewart Warner Factory Design Drawing |

|

Readings and FunctionPosted by Greg Rose on 12/07/03 and updated on 02/16/04The cable turns a magnet that in turn moves the speedo needle. The clock spring holds the correct amount of tension to cause the magnet to "slip" enough to read the right MPH. The cable (and pinion) turns at 1000 revs per mile I'm gonna assume the MPH thing you measured is gospel (i.e., clock spring adjustment is spot on). I'd rather you drove a know distance, say between 10 mile markers, and record your odometer reading - then decide what that difference is. First - count the teeth in the gear you now have (forget the colors for now) .Your speedo is off by 12 MPH or 21.8%. You need 21.8% MORE teeth (in the future remember fast=MORE, slow=LESS). Assuming your current pinion gear has 34 teeth you need 34 X 0.218 = 7.4 more teeth or 41 teeth. By the way, that's P/N 2538941 (red). Seems like an awful lot?! Read further. HOW TO TRUE-UP YOUR SPEEDOA little background on the Chrysler speedo. The pinion gear in the tranny case is correct when it turns the speedo cable 1,000 revolutions per mile. So the other end of the cable in the speedo spins a magnetized bar at 1,000 revolutions per mile. The magnet causes the speedo needle to move as it spins. A clock spring applies the correct tension on the needle to assure accuracy and prevent it from bouncing wildly, thus smooth operation. The speedo also steps the cable down by 1000:1 so it turns the tenths odometer wheel one full revolution per mile. The tenths wheel then moves the next wheel (miles) one tenth of a revolution, and so on, and so on. The key is to match the pinion gearing to achieve 1000 revs per mile. In order to do this we need a standard to match the speedo against. It can be done on a bench with a known motor RPM driving the speedo - but that won't account for your "in-car" set-up of wheel height, rear gear ratio, etc. The following method will account for these variables and result in a very accurate gauge. One last thing - I've heard many discussions on using wheel height, rear gear, tranny final gear ratio, etc. and doing the pure math based calculation. You can get close, maybe right on it - but I believe the following method to be the easiest and absolutely most accurate. Okay, here we go:1. Record your beginning odometer reading to the nearest tenth of a mile (if you'd like to estimate between tenths- even better!) 2. Drive a known distance. Mile marker are great for this. Drive at least 2 or 3 miles. 10 is better and the math is easy, too! 3. Record your ending odometer reading as in Step #1 above. 4. Pull the pinion gear from the tranny by removing the speedo cable and the adapter clamp bolt. Slips right out. Watch for the red flood - tranny fluid. I like to put the rear end on jack stands to move the fluid to the front and spill less. Anyway - count the teeth of the pinion gear. 5. We now have all the data we need to "get accurate"! Here's the example: Current Pinion Gear Teeth = 33

6. 1.60 miles too far divided by the actual distance of 10 miles = 0.16 OR 16% ; our speedo is reading 16% HIGH - OR TOO FAST. We need 16% more teeth! 7.

33 + 5 = 38 teeth. The pinion gear with 38 teeth is P/N 52068060 (blue) 8. Change out the 33 tooth pinion gear for a new 38 tooth gear and BINGO - we are spot on. Do the test over to confirm and happy motoring!! This doesn't promise an absolutely accurate speedo, as the clock spring tension is the adjustment for that. If the clock spring is okay and the main reason for the inaccuracy was a tire size change or rear gear change - bet you're in fine shape. The speedo clock spring tension can be adjusted (more tension = slower reading, less = faster) but it's a delicate process that might be best left to a speedo shop. |